Henchman Mask Vacuum Form Tutorial

INTRODUCTION

So Dragon*Con 2011 has come and gone, Venturoos. Despite a year’s worth of intense research and sculpting on my Daft Punk helmets, I was totally surprised (read: blown away) by the outrageously positive response my Monarch’s Henchmen costumes received at the convention. I figured, you know, shiny shiny, Daft Punk, slick tuxedos. It’s a sure bet, right? Nope! With near surgical precision and timing (and no small amount of devious…ness…), the Monarch stole the show, and it was his minions that did the dirty work.

Wait, wait. Really? Secondary characters from a show that’s a few years old now… surely these costumes must be overdone! Ah, but not done the 2StoryProps way! Ok that was exceptionally cheesy. In particular, it was my vacuum-formed masks that really got all the attention. You see, most people are happy with trimmed cardboard or bent plastic, and it certainly achieves the cartoony look. However, I set out to make the highest quality mediocre costume I could, and I wanted it to have some real-world depth to it. I’d like to think that the costume as a whole caught everyone’s attention, but the fact that everyone kept complimenting the vacuum-formed masks really speaks volumes about the methods used here.

This tutorial will take you through the process, methods, and tools used to create your own vacuum-formed Henchmen mask. The powers-that-be have informed me that this is to be an expert-level tutorial, so basic knowledge and skills on power tool usage and safety are required. Also note: You will be using sharp things, so don’t stab yourself on my account.

SUPPLY LIST

Tools:

Dremel or other rotary tool with interchangeable cutting/sanding bits

Power sander with 120 grit sandpaper

120-320 grit sand paper (for hand sanding)

Steak knife or bread knife (Really? You betcha.)

Vacuum-forming machine or access to one

Supplies:

HARD green floral foam blocks (the really hard stuff, not the softer powdery stuff)

Toothpicks

Gorilla glue

Bondo or body filler of choice

Your choice of glazing putty (for small pits)

Primer spray paint of your choice

Miscellaneous:

Respirator or dust mask

Safety goggles

Latex or vinyl gloves

Clothes you don’t mind getting dirty

SCULPTING THE MASK

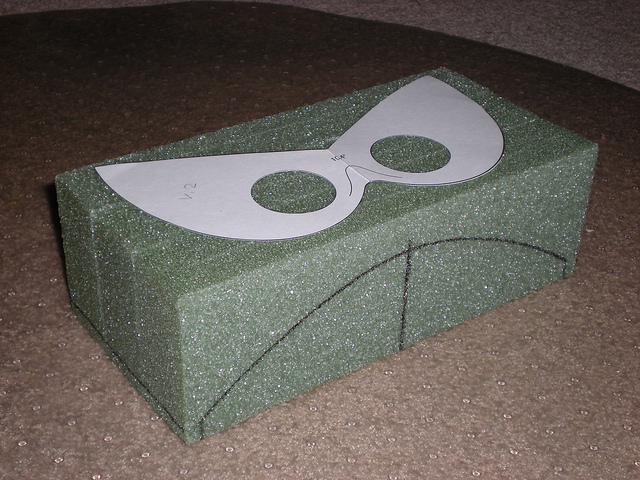

First thing’s first – you have to know what you’re sculpting. I drew out my design, which I based on several distinct views of the Henchmen mask from the show. I decided on a certain shapes and came up with a quick schematic in Adobe Illustrator. Nothing special about this part, you can just draw it out to scale on some printer paper if you’d like. The point here is that you have something to go by. Since you’ll be drawing this directly onto the foam in a later step, go ahead and cut out your drawing (eye holes and everything).

Next you’ll want to assemble your foam blocks. Decide how big of a block you need and then glue multiple blocks together with Gorilla Glue. It’d be a good idea to pin them together with toothpicks and bind the blocks up with some tape while the glue dries. Gorilla Glue expands while it cures, so anything you can do to keep those blocks together while the glue dries will be helpful. It’ll take a few hours, so go watch some Venture Bros. while you wait. I don’t have any photos of this part because it’s gluing blocks of foam together. It’s not rocket surgery science, people!

After that’s done, go ahead and start tracing out your design on the block. Keep in mind, you’ll be cutting away a lot of the foam, so keep your template handy so you can redraw it later as you remove material.

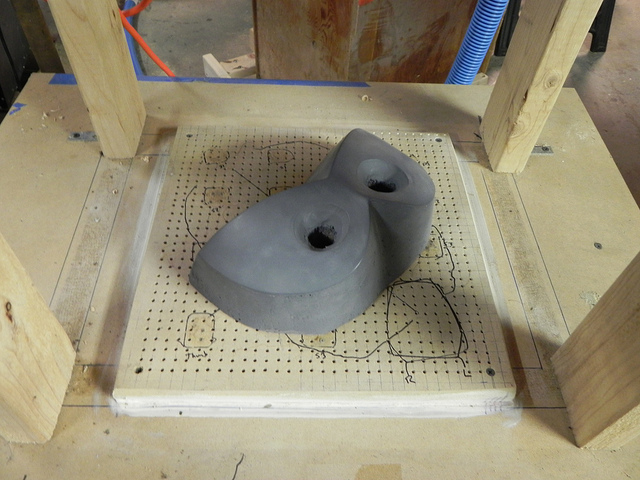

Remember how I wanted that real-world feel? I achieved that by sculpting in curves, giving it a 3D shape in addition to the curve around the face the mask would naturally have. Now this particular floral foam was chosen because it’s rather rigid and I knew it would hold up enough under the pressure of a vacuum-forming machine. As such, it takes some elbow grease to sculpt it. So here’s where the steak knife comes in handy. You don’t have to use a steak knife, but as long as you have some kind of serrated blade that can slice into it you’ll be fine. Do your sculpting by shaving off thin layers. Don’t get overzealous and try to cut off large chunks. Your blade will only seize up in the foam. You can try power tools, but I’ve found that hand carving it produces far less debris and dust. At this point you’re really only looking for basic shape. You can start to carve in some details (like the curve of the bridge of the nose or the goggle sockets, but if you carve a little too deep in an area, don’t worry about that right now.

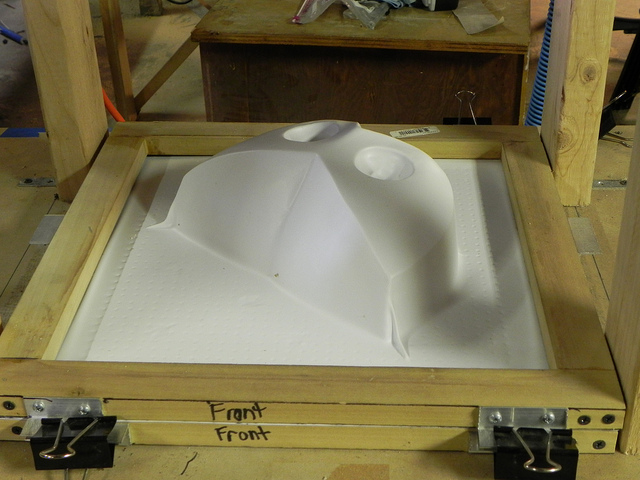

Next comes the smelly part. Be sure to wear your respirator here. To get the nice, smooth surface on the foam, cover it in Bondo (or any body filler of your choice). You’ll want to be sure that it’s really ground into the foam, so you’ll do it in layers, gradually building up so that you don’t see any foam left. While the Bondo cures, you can carve it with a box cutter to reduce any big peaks and smearing streaks. Doing so will help save the sandpaper on your power sander. Give the Bondo a few hours to get rock hard. Keep in mind, Bondo requires certain temperatures and cannot cure above a certain humidity, so be sure to read the package for ideal conditions.

Use your power sander and dremel to smooth the Bondo out into the final shape. When you start getting to the point where all that’s left to fill is smaller holes, use the glazing putty to fill in the gaps, and then sand it all smooth. In the photo below, the whitish areas are Bondo, the pink and red areas are glazing putty.

Knowing how vacuum-forming works its critical to the design of your vacuum-forming buck, so you’ll need to bore a hole through each eye socket all the way through the foam. The reason behind this is because as the heated plastic is pulled over the buck, it will essentially seal up around the eye sockets. If there is no way for the vacuum to pull the plastic down into the eye sockets, the plastic will remain flat in those areas. So you have to provide a channel for the air to be sucked out the back of the buck. For this particular project, it doesn’t have to be pretty since this area will be cut out later, but just be sure that it’s there.

Continue sculpting and smoothing with the Bondo until you have your desired shape. It may take you some time depending on your abilities, but be sure you get it nice and smooth. In previous projects we learned that even a bit of dust can cause unwanted peaks in vacuum-formed plastic, so spend some time here and get it really smooth. Spraying it with primer between each smoothing session allows you to see the form in a neutral color, and it helps point out problem areas. You should be wrapping up your sculpt by the end of this stage.

VACUUM FORMING

While we did build our own vacuum-forming machine, it was not based on our own design. We followed the build of a friend and fellow prop builder, Volpin Props, to learn how to build our own machine. Since building the machine itself is not within the scope of this tutorial, I will instead refer you to Harrison’s blog post on how he built his.

Provided that you have your own vacuum-forming machine (or at least access to one), the next step is to select your plastic. There are lots of vacuum-formable plastics out there, but our projects tend to involve clear PET plastic and white styrene. Either will work for this particular project. For the rest of this tutorial, I will be using white styrene to pull the mask. However, my initial pulls were made in some left-over clear PET plastic from a previous project, and that worked just as well. The eye pieces were also pulled in clear PET plastic, FYI. For your reference, here are some links to the plastics I typically use:

.60″ High Impact Styrene Sheet

Please note: When selecting plastics, you should always read up on its characteristics. You should always practice safe vacuum-forming. The process involves heating plastic, which releases toxic fumes, so PLEASE be in a well ventilated area and wear your respirator. Also, ALWAYS have a fire extinguisher on hand – if you heat the plastic too rapidly IT WILL IGNITE and make for a very bad day.

Vacuum-forming works on the basic principle that you are heating a sheet of plastic so that it becomes temporarily elastic enough to be formed over the outside of a 3D shape (a “buck”), pulled into that shape by a vacuum, and allowed to cool in that shape. The buck is removed and then the plastic is trimmed and built into your final piece. Our particular machine has a heating element in the top section that we are able to clamp a sheet of plastic into place underneath it (the plastic itself is held in with a wooden frame), and a vacuum base on the table top that allows us to simply lower the heated plastic down onto.

Now because each individual vacuum-forming machine will operate uniquely to itself, I cannot provide any heating times or ideal temperatures for you. That’s something you’re going to have to play around with on your own. However, I will tell you that it’s best to heat the plastic slowly! As I said before, if you heat it too quickly, it can ignite. Aside from that, the important thing is to let the plastic droop. You’ll want to let it droop as much as it can, and that allows it to form easily to your buck, and it can prevent a problem I’ll refer to later as “webbing.”

I’ve prepared a video of what vacuum-forming looks like. Due to the cluttered background, I chose to focus only on the vacuum base itself. Understand that by the time the video started recording, the plastic had been heating for about 20 minutes or so and the plastic was allowed to reach it’s “maximum droopage.”

When the plastic is pulled down, it’s best to let it sit there under the pressure of the vacuum for several minutes while the plastic cools. Otherwise it may try to spring back a little, and you could lose some definition in the pulled plastic. Generally the plastic cools rather quickly, so once our heating element is warmed up, we can run through several pulls in an hour.

Earlier I referred to a problem I call “webbing.” I’m not sure if it’s the correct term, but it’s what I’ve been referring to it as. Basically it’s what happens when the plastic is pulled over a sharp enough shape in the buck that two sides of the plastic are pulled into each other before they are pulled into the vacuum base. You can’t really correct it on the fly, but sometimes you’re able to ignore it completely if the webbing doesn’t touch the usable portion of the plastic you just pulled. Below is an example of that. You can see where the plastic is forming a fold at the tips of the buck. However, since I’ll be trimming the mask quite close to the front face, the webbing on this particular pull doesn’t affect the final product.

Unfortunately, at the time I took these photos and shot the video, I didn’t have any clear PET plastic with me to pull a set of eye pieces. However, the process is the same. The only difference is that I made a quick mold of my original eye piece model so that I could cast several copies up and pull a whole sheet of eye pieces at once (instead of one at a time).

How you choose to finish your project is up to you. Thinner plastics can be trimmed with shop shears or an X-acto knife, and you can use a Dremel as well. Since my personal masks were thinner PET plastic, I used an X-acto blade to trim the outer edge, and then I used a Dremel with a sanding drum to cut the eye holes out. Wear eye protection when using a Dremel since PET and ABS tend to throw out little chunks of melted plastic when you use a power tool on them. Also be sure to wear your respirator since both PET and ABS are plastics and the fumes from cutting them with power tools are harmful. Top finish up the edges hand-sanding on these kinds of things makes for a nice, smooth edge. I would recommend against using any sort of power sander on these materials because you can end up removing a lot more material than desire really quickly.

For final assembly, I chose to paint the mask and eye pieces, and then glue the eyes to the mask wit hot glue. The mask was painted with Krylon Fusion “Sunbeam Yellow” (which as close to the particular yellow of the masks in the show as I could find locally) and the lenses were painted with Krylon Stained Glass Red. A black elastic band was attached to the backside of the mask with some J B Weld, and then I lined the nose area with some thin black foam for comfort.

Well I hope this tutorial was informative and scientastic. I wrote it over the course of about 3 days, so I hope it’s rather seamless.

Written by David Reimer, 2 Story Props

Discuss this story in our Venture Forums! Follow @VentureBrosBlog on Twitter and be sure to “LIKE” us on Facebook for the latest Venture Bros. news!

[Venture Bros. Blog]